Metal Effect Powder Coating

General Introduction:

It can provide metal effect powder coatings of mixed type, pure polyester type and other resin types, thermosetting powder coatings with excellent Physical properties, chemical properties and decorative properties. Suitable for indoor or outdoor use. This product has a unique and luxurious appearance decoration effect, widely used in the surface coating of home appliances, cooking utensils, instrument shells, electromechanical equipment, indoor furniture, auto parts, etc.

Product Series:

to provide highlights (80% above), semi-light (50-80%), plain glass (20-50%) and no- light (20% below) products or on requirements

Physical Properties:

Specific gravity(g/cm3, 25℃): 1.4-1.7

Particle size distribution: 100 % less than 100 micron (It can be adjusted according to the special requirements of coating)

Construction Conditions:

Pretreatment: Different pretreatment for different substrates (phosphating treatment, sand blasting treatment, shot peening treatment)

Curing mode: manual or automatic static gun construction

Curing conditions: 200℃(workpiece temperature), 10 minutes

Coating performance:

|

Testing item |

Inspection standard or method |

Test indicators |

|

impact resistance |

ISO 6272 |

50kg.cm |

|

cupping test |

ISO 1520 |

8mm |

|

adhesive force(row lattice method) |

ISO 2409 |

0 level |

|

bending |

ISO 1519 |

2mm |

|

pencil hardness |

ASTM D3363 |

1H |

|

salt spray test |

ISO 7253 |

>500 hours |

|

hot and humid test |

ISO 6270 |

>1000 hours |

|

heat resistance |

110℃/24 hours (white) |

excellent light retention, color difference≤0.3-0.4 |

Notes:

1.The above tests used 0.8mm thick cold-rolled steel plates with a coating thickness of 50-70 microns.

2.The performance index of the above coating may decrease slightly with the decrease of gloss.

Average Coverage:

9-12 sq.m./kg; film thickness 60 microns (calculated with 100% powder coating utilization rate)

Packing and transportation:

cartons are lined with polyethylene bags, net weight is 20kg.Non-hazardous materials can be transported in various ways, but only to avoid direct sunlight, moisture and heat, and avoid contact with chemical substances.

Storage Requirements:

Store in a ventilated, dry and clean room at 30℃, not close to the fire source, central heating and avoid direct sunlight. It is strictly prohibited to pile up in the open. Under this condition, the powder can be stored for 6 months. After the storage life can be re-examined, if the results meet the requirements, can still be used. All containers must be repackaged and repackaged after use.

Notes:

All powders are irritating to the respiratory system, so avoid inhaling powder and steam from curing. Try to avoid direct contact between skin and powder coating. Wash skin with water and soap when contact is necessary. If eye contact occurs, wash skin immediately with clean water and seek medical attention immediately. Dust layer and powder particle deposition should be avoided on the surface and dead corner. Tiny organic particles will ignite and cause explosion under static electricity. All equipment should be grounded, and construction personnel should wear anti-static shoes to keep the ground to prevent static electricity.

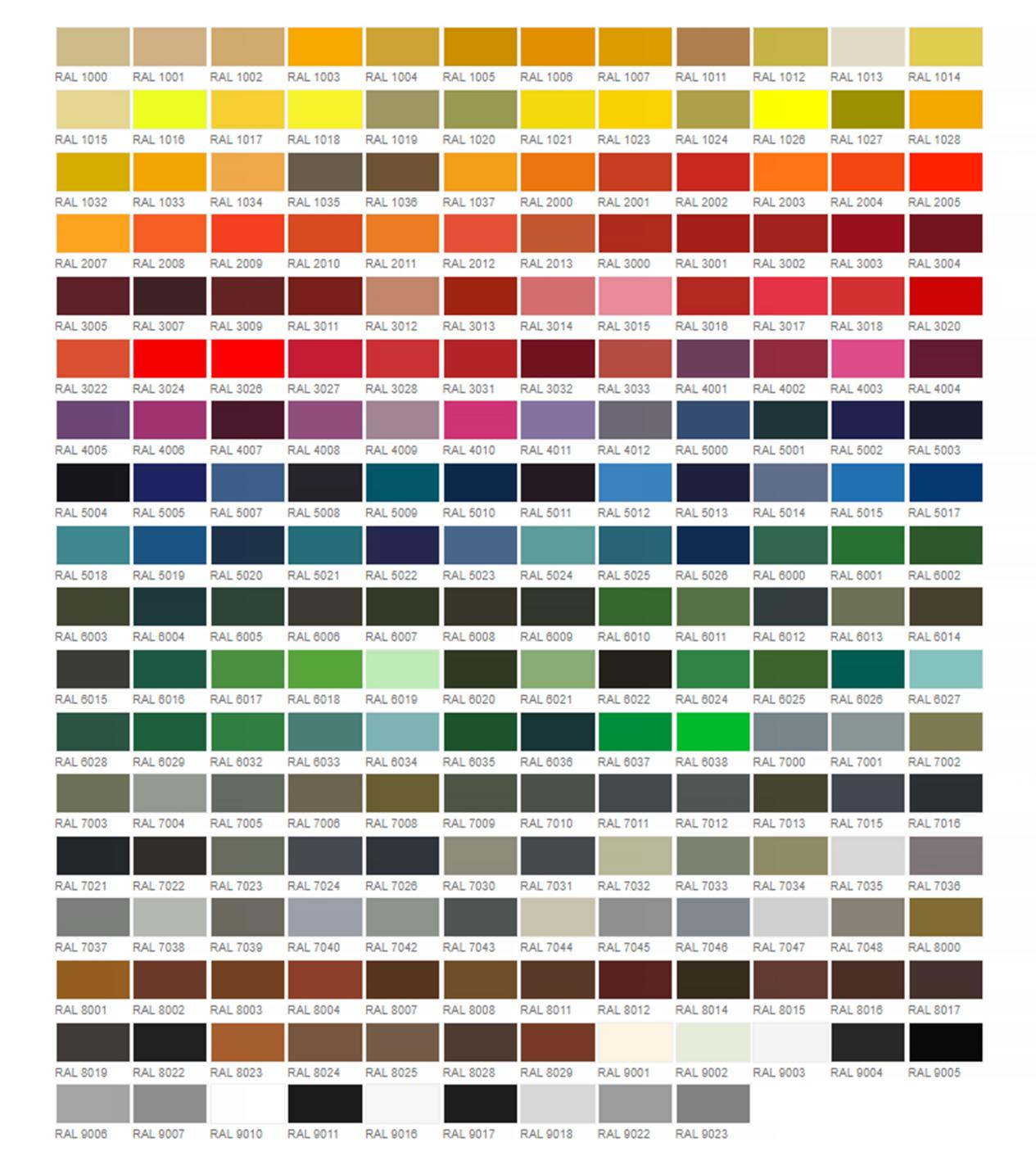

Any color is available in Colorcom: