FRP with sand pipe (RPM) | GRE COMPOSITES VALVE | Water Treatment Plant

Product Specification:

|

Rigidity |

SN2500 |

SN5000 |

SN10000 |

|||||||

|

Pressure(Mpa) |

0.25 |

0.6 |

1.0 |

0.25 |

0.6 |

1.0 |

0.25 |

0.6 |

1.0 |

1.6 |

|

DN300 |

|

|

|

|

7.2 |

7.2 |

|

7.2 |

7.2 |

7.2 |

|

DN350 |

|

|

|

|

8.2 |

7.6 |

|

8.2 |

8.2 |

7.6 |

|

DN400 |

|

|

|

|

8.2 |

7.6 |

|

8.5 |

8.2 |

7.6 |

|

DN500 |

7.2 |

7.2 |

7.0 |

8.5 |

9.0 |

8.6 |

11.1 |

11.3 |

10.6 |

9.2 |

|

DN600 |

8.4 |

8.6 |

8.3 |

10.5 |

10.8 |

10.0 |

13.4 |

13.4 |

12.4 |

11.9 |

|

DN700 |

9.8 |

9.6 |

8.3 |

12.3 |

11.9 |

11.5 |

15.5 |

15.1 |

14.2 |

13.4 |

|

DN800 |

11.2 |

10.7 |

9.8 |

14.0 |

13.3 |

12.9 |

17.8 |

16.8 |

16.1 |

14.9 |

|

DN900 |

12.5 |

11.9 |

10.8 |

15.8 |

15.5 |

14.2 |

20.0 |

19.0 |

17.8 |

16.7 |

|

DN1000 |

13.9 |

13.2 |

12.3 |

17.5 |

16.6 |

15.8 |

22.2 |

21.2 |

19.7 |

18.2 |

|

DN1100 |

15.4 |

14.5 |

13.6 |

19.3 |

18.3 |

17.2 |

24.6 |

23.4 |

21.7 |

20.8 |

|

DN1200 |

16.0 |

15.5 |

14.5 |

21.0 |

18.4 |

18.6 |

26.8 |

25.0 |

23.3 |

21.8 |

|

DN1300 |

18.1 |

16.7 |

15.6 |

22.9 |

21.5 |

20.0 |

29.2 |

26.9 |

25.5 |

23.6 |

|

DN1400 |

19.5 |

17.7 |

16.4 |

24.6 |

22.4 |

21.5 |

31.2 |

28.6 |

27.0 |

25.5 |

|

DN1500 |

20.7 |

19.0 |

17.7 |

26.1 |

24.4 |

23.5 |

33.3 |

30.4 |

29.6 |

27.1 |

|

DN1600 |

21.8 |

20.5 |

19.2 |

27.8 |

26.0 |

24.5 |

35.4 |

33.3 |

31.0 |

28.9 |

|

DN1800 |

24.6 |

22.6 |

20.4 |

31.3 |

28.8 |

26.8 |

39.9 |

36.9 |

34.1 |

31.3 |

|

DN2000 |

27.4 |

25.4 |

23.4 |

35.0 |

32.4 |

29.6 |

44.7 |

38.2 |

37.3 |

36.1 |

|

DN2200 |

29.7 |

27.6 |

25.3 |

37.8 |

35.3 |

32.6 |

48.7 |

42.5 |

41.5 |

40.4 |

|

DN2400 |

32.6 |

30.3 |

28.4 |

41.8 |

38.8 |

34.6 |

53.4 |

45.8 |

44.6 |

42.8 |

|

DN2600 |

36.3 |

33.5 |

31.5 |

45.2 |

40.5 |

35.4 |

55.8 |

48.9 |

47.2 |

45.6 |

|

DN2800 |

39.3 |

36.0 |

34.0 |

49.4 |

45.1 |

42.0 |

62.0 |

56.5 |

53.0 |

51.0 |

|

DN3000 |

41.0 |

38.1 |

36.2 |

52.0 |

47.0 |

45.3 |

67.0 |

61.7 |

58.2 |

54.0 |

Comparing with different material pipes:

|

Material Item |

FRP pipe with sand | Concrete pipe with steel jacket | Concrete pipe | Steel pipe | Casting pipe |

| Crude coefficient | 0.0084 | 0.013 | 0.013 | 0.01 | 1.011 |

| Anti-seepage | Very good anti seepage | Better on the pipe | normal | good | Better than steel pipe |

| Anti corrosion | Excellent,need not other anti-corrosion treatment | Need anti-corrosion treatment in some special situation,and cathode protection | Need anti-corrosion treatment in some special situation,and cathode protection | Bad ant-corrosion need good protection | Some situation need protection |

| Safety(no toxicity,pollution) | Can be used in drink water | No toxicity,no pollution to water | No toxicity,no pollution to water | Easy rust,have pollution to water | Easy rust,have pollution to water |

| Connecting way | Double”o”seal,socket connection | Slide rubber single seal,socket connection | Elastic rubber seal | welding | socket |

| Connector angle tolerance with axis | Reach 3 | Reach 3 | Can not do | ~ | ~ |

| Connector pressure testing | Can do | Can not do | Can not do | Can not do | Can not do |

| Installation speed | Very quick | normal | lower | ~ | normal |

| Pipe blasting opportunity | no | have | have | have | have |

| maintenance | Normally need not maintenance.if need,it is very easy | Not easy | Not easy | Not easy | Not easy |

Product Description:

High strength,lower weight,quick installing

Strong resistance to erosion

Good hydrodynamic performance,save piping pump energy.

Excellent insulation. Designable easily

Lower maintenance fee,saving engineering fee over 70%.

Long working life, high responsibility, good engineering profit,Larger diameter, lower cost

Non-toxic, can transport drinking water

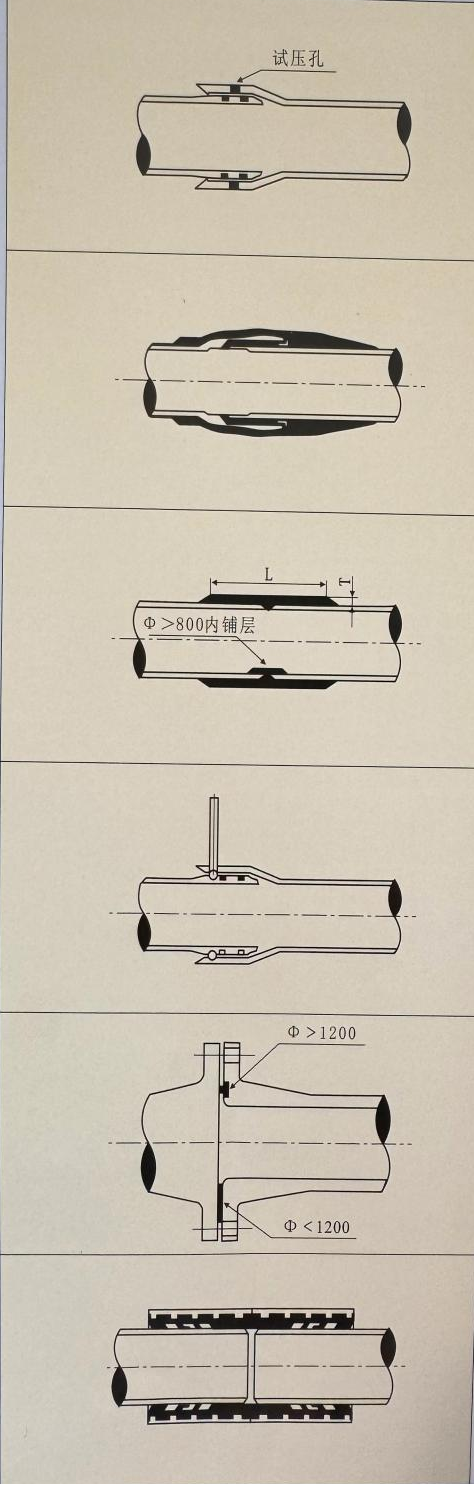

Connection way of pipes:

| 1.Double seal socket connectionIt is suitable for FRP pipe with sand when ground pipe with

high pressure. It can do one connector pressure testing. |

| 2.Socket adheringit is suitable for CPVC,PVC,PP/FRP high pressure and

complex loading big diameter piping. |

| 3.Connecting face to faceIt is suitable for High, middle, low pressure piping and

fitting connection. L and T deal with application situation. |

| 4.Socket“O”seal connecting Nylon pole key lockIt is suitable for the piping with lager vertical elongating stress, such as deep well pipe. |

| 5.Flange connectionJB、GB、ASTM、DIN、NF、JIS

It is suitable for middle and low pressure piping and 1200 equipment. It uses HG, JB, GB, ASTM, DIN, NF, JIS standard. |

| 6.Glove connectionIt is suitable for middle and low piping and short piping.

It can be applied in connecting with metal or other materials. |

Application:

Chemical industry,paper industry,waster water treatment,desalinator.pharmaceutical industry,HVAC,chimney.

Pipes transportation,storage and installation:

1.Pipes can not connect each other from side to side. It must be separated by the cushion wood. The storage layer highness should be lower than 2 meter.The pipe can be gloved for different diameter, but need prevent any damage the pipe wall.

2.Avoid any strong impact when transportation and loading.

3.Pipes need storage on flat ground. The storage highness should be lower than 2 meter. Storage place need far away the fire.Avoid long period storage outside.

Installation:

There are three kind of piping installation: over head, on the ground, under the ground.

1.over head installation

1.1Because of lower elastic to Composite and FRP pipes,it need suitable design for supporting and span.For decreasing connector stress,supporters need near connectors.The lock can not be very tight,to keep enough space for temperature expanding.

1.2Pipe supporters have hooks, supporters, foots. They need keep connection with pipe wall over 180.On the supporters the rubber cushion need be over 3-5mm thickness and fasten by bolts.

1.3The connecting between Pipe and pipe,pipe and fittings,need be according to the process.

1.4Any warp when installation,on the horizontal should be ≤2-3/1000,on the vertical≤2-5/1000, on the slope 3/1000 of span of two supporters.

1.5Layout of piping and type should be meet requirement on loading,tolerance and settlement.The span is designed according to liquid density of 1.3,and-10~75℃temperature.For detail,please refer to data sheet.

1.6When bolts connect flange,be attention on distort and support pole to avoid over distort to damage the flange.

2.installation for under ground pipes

There are special consideration for under ground pipes.Except above items,the slot need to be made of tile with short supporters.The depth of slot is >400 mm for pavement,and>700mm for truck road.It can be calculated according to Jansen formular.Normally,it is 2 times of diameter,but not less than 500 mm.when burying,need avoid any stone in the soil,then compaction.If necessary,the concrete cover can be used.

|

DN |

NORMAL SPAN OF THE PIPE |

||

|

-10~30℃ |

31~50℃ |

51~75℃ |

|

|

25 32 40 50 65 80 100 125 150 200 250 300 350 400 450 500 600 700 800 1000 1200 1400 |

2.3 2.5 2.6 2.8 3.0 3.1 3.3 3.4 3.6 3.9 4.1 4.4 4.6 4.8 5.0 5.2 5.6 5.8 6.0 6.4 6.8 7.2 |

2.3 2.4 2.6 2.8 2.9 3.1 3.2 3.3 3.6 3.8 4.0 4.3 4.5 4.6 4.8 5.1 5.5 5.7 5.9 6.3 6.7 7.1 |

2.2 2.4 2.5 2.7 2.8 3.0 3.1 3.2 3.5 3.7 3.9 4.2 4.3 4.5 4.7 4.9 5.3 5.5 5.7 6.1 6.5 6.9 |

FAQ:

1. Are you a manufacturer or trading company?

We are professional manufacturers of Melatonin since 1999. Welcome to visit our factory for long-term cooperations.

2. How do you ensure your product and service quality?

All of our processes strictly adhere to ISO 9001 procedures and we always final Inspection before shipment.We are equipped with state of the art quality control facilities.

3. What's your MOQ?

For the high value product, our MOQ starts from 1g and generally starts from 1kgs. For other low price product, our MOQ starts from 10kg and 100kg.

4.Can you send free samples?

Yes, we can send free samples for most products. Please feel free to send inquiry for specific requests.

5. How about the payment?

We support most mainstream payment methods. T/T,,L/C, D/P, D/A, O/A, CAD,,Cash, Western Union, Money Gram, etc.

6.Do you offer technical supports for the products?

Yes, we have a professional technical support team and can provide unique technical solutions to our clients.