Fluorescent Brightener KCB | 5089-22-5

Product Description

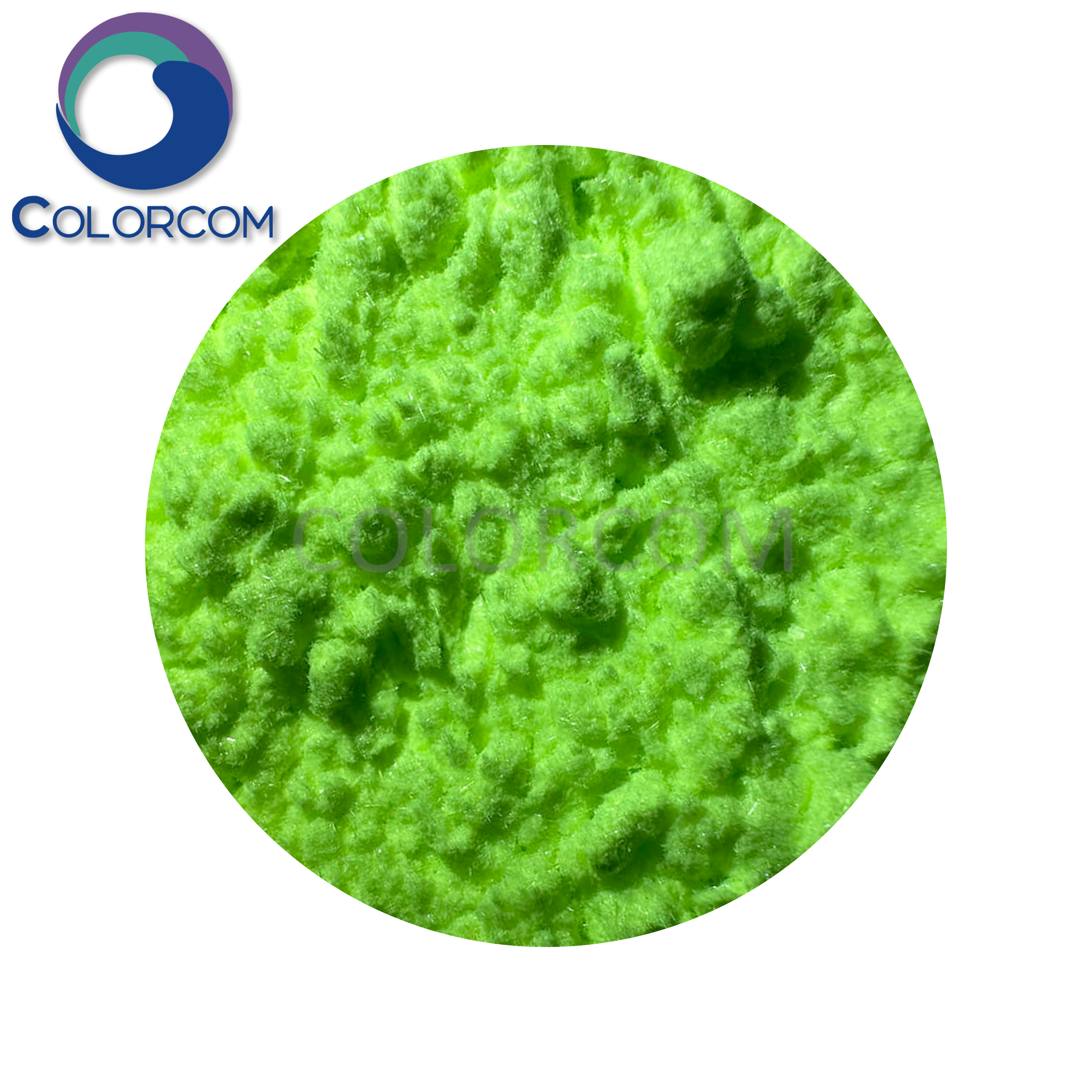

Fluorescent Brightener KCB is a benzoxazole fluorescent brightener with yellow-green powder appearance and blue-white fluorescence. It is soluble in toluene, acetone, trimethylbenzene, polyvinyl chloride, carbon tetrachloride and dimethylformamide, with a maximum absorption wavelength of 370nm and a maximum fluorescence emission wavelength of 437nm. It has the characteristics of good compatibility, not easy to precipitate, low addition and good whitening effect, and has excellent heat and light resistance, and does not react with foaming agents and cross-linking agents.

Other Names: Fluorescent Whitening Agent, Optical Brightening Agent, Optical Brightener, Fluorescent Brightener, Fluorescent Brightening Agent.

Applicable industries

Whitening masterbatches, foaming masterbatches, filling masterbatches, functional masterbatches, flame retardant masterbatches and other colour masterbatches.

Product Details

|

C.I. |

367 |

|

CAS NO. |

5089-22-5 |

|

Molecular Formula |

C24H14N2O2 |

|

Moleclar Weight |

362 |

|

Appearance |

Yellow-green crystallione powder |

|

Melting Point |

210-212℃ |

|

Colered Light |

Bright blue-white light |

|

Fineness |

≥ 100 item |

|

Max. Absorption Wavelength |

370 nm |

|

Max. Emission Wavelength |

437 nm |

|

Application |

It is mainly used in the whitening of plastic and synthetic fibre products, and also has an obvious brightening effect on coloured plastic products. It is also used in large quantities in ethylene/vinyl acetate (EVA) copolymers and is a suitable fluorescent whitening agent for sports shoes. It is also widely used in PE, PP, PVC, PS, ABS, PMMA and other plastic films, molding materials, injection molding materials and polyester fibers. It also has a good effect on the whitening of paints and natural lacquers. |

Reference Dosage

1.For plastics or resins, the general dosage is 0.01-0.03%, i.e. about 10-30 grams of fluorescent whitening agent per 100 kg of plastic material. (Users can adjust the specific amount of whitening agent according to the whiteness requirements. If UV absorbers such as titanium dioxide are added to the plastic raw materials, the amount of whitening agent should be adjusted appropriately. )

2.PE material whitening agent reference dosage: 10-25g/100kg.

3.Plastic material PP material whitening agent reference dosage: 10-25g/100kg plastic material.

4.PS material whitening agent reference dosage: 10-20g/100kg plastic material.

5.PVC material whitening agent reference dosage: 10-30g/100kg plastic material.

6.ABS material whitening agent reference dosage: 10-30g/100kg plastic material.

7.EVA material whitening agent reference dosage: 10-30g/100kg of resin.

8.If used in transparent plastic film, the reference amount of whitening agent: 1-10 g/100 kg of plastic material.

Product Advantage

1.Stable Quality

All products have reached national standards, product purity of more than 99%, high stability, good weatherability, migration resistance.

2.Factory Direct Supply

Plastic State has 2 production bases, which can guarantee the stable supply of products, factory direct sales.

3.Export Quality

Based on domestic and global, the products are exported to more than 50 countries and regions in Germany, France, Russia, Egypt, Argentina and Japan.

4.After-sales Services

24-hour online service, the technical engineer handles the whole process regardless of any problems during the use of the product.

Packaging

In 25kg drums (cardboard drums), lined with plastic bags or according to customer’s requirements.